Threaded fasteners—those humble screws, bolts, and nuts—form the invisible skeleton of industrial civilization. From the aerospace sector to automotive manufacturing, from assembly lines to infrastructure development, the integrity of the modern world rests on their mechanical reliability.

Yet, the act of tightening a bolt is not a trivial matter. Beneath its surface lies a complex interplay of torque, tension, joint design, material science, and tool engineering. This essay explores the scientific principles and engineering practices that govern the world of tightening techniques.

I. The Ubiquity of Threaded Fasteners: Why Screws Still Matter

Threaded fasteners remain the most prevalent method of joining mechanical components. Their advantages—modularity, repeatability, ease of disassembly, and cost-efficiency—outstrip other joining methods like welding, soldering, or riveting in most production environments. Screws are especially valuable in industries that demand both precision and serviceability, such as electronics, aviation, and automotive assembly.

Unlike permanent methods, threaded fasteners enable maintenance, reconfiguration, and upgrades. This makes them ideal for systems where lifecycle flexibility and repairability are key, especially as industries move toward sustainability and circular economies.

II. The Screw Joint as a Mechanical System

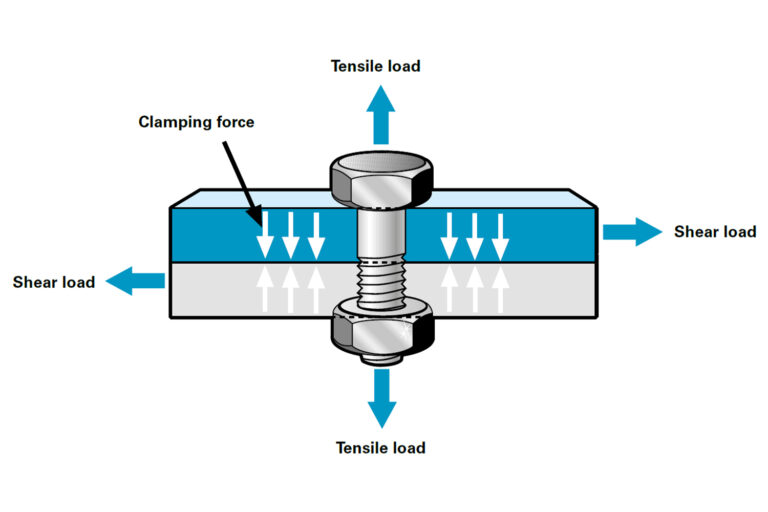

A screw joint is not merely a connection, it’s a mechanical system designed to carry loads, maintain frictional stability, and resist failure modes. When a screw is tightened, it is subjected to multiple forces:

- Tensile Load: The clamping force that pulls the components together.

- Torsional Load: Induced by the torque applied during tightening.

- Shear Load: Occurs when external forces attempt to slide components perpendicular to the screw axis.

An optimal joint design maximizes tensile load resistance while minimizing exposure to shear forces. This is especially important in friction joints, where surface friction between joined components is expected to bear shear stresses. Poor joint design can lead to catastrophic failure—particularly if the tensile capacity is exceeded due to incorrect torque application or external overload.

III. Clamping Force: The True Metric Behind Torque

While torque is the most commonly controlled variable during tightening, it is not the end goal. The real objective is to achieve an adequate clamping force, which is the axial load that maintains the integrity of the joint. Unfortunately, clamping force cannot be directly measured in production environments. Instead, it is inferred from torque and angle—both of which are influenced by material properties and friction.

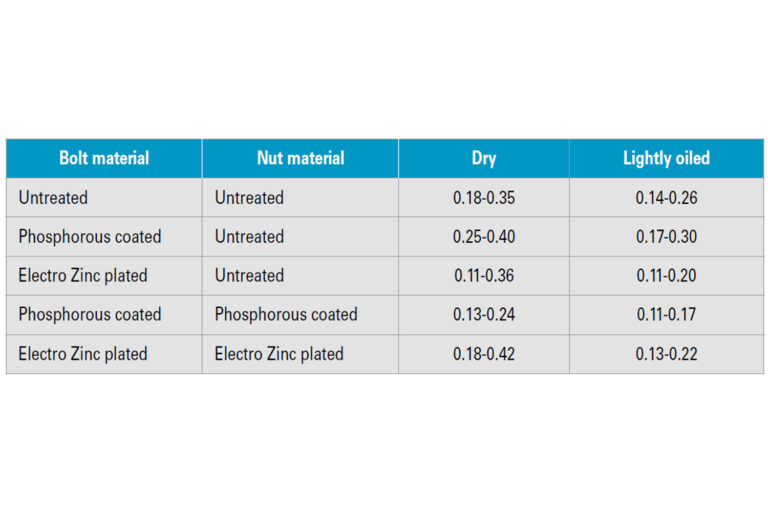

Only about 10% of the applied torque contributes to clamping force. The rest is lost to friction—40% in the threads and 50% under the screw head. This inefficiency highlights the delicate balance between tool performance, lubrication, and material compatibility.

IV. The Role of Lubrication: Friend and Foe

Conversely, dry fasteners often result in under-tightening due to elevated friction. This compromises the clamping force and risks joint loosening under dynamic loads. Thus, understanding the friction coefficient of different material pairings—untreated, plated, or coated—is essential for setting reliable torque values.

V. Material Strength and Screw Classification

Screws are classified by material strength using a standardized two-digit system. For example, a Bolt Grade 8.8 has a minimum tensile strength of 800 N/mm² and a yield strength of 640 N/mm² (0.8 × 800). Higher-grade fasteners (e.g., 10.9 or 12.9) can handle higher stresses but are more susceptible to issues like hydrogen embrittlement or thread stripping if improperly handled.

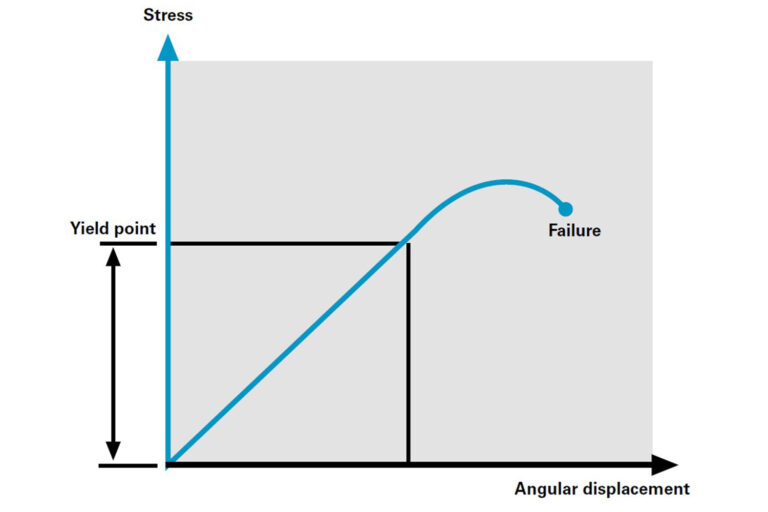

The tightening process must be calibrated to the material properties of the screw to prevent entering the plastic deformation zone, beyond which the screw will not return to its original form. Tightening into this plastic region may be deliberate in specialized applications requiring precision clamping, but it demands tight process control.

VI. Hard Joints vs. Soft Joints: The Torque Rate Dilemma

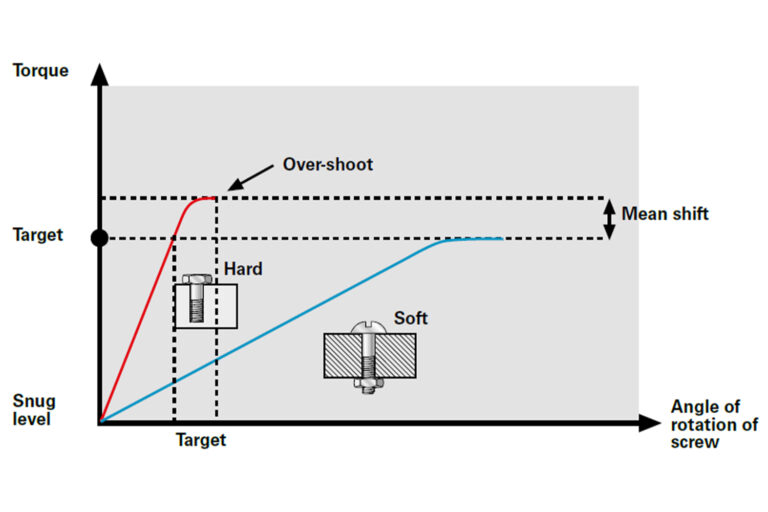

The behavior of a screw joint is largely defined by its torque rate—the angular displacement needed to achieve the desired torque beyond the snug point. This leads to the distinction between:

- Hard Joints: Rigid assemblies with minimal compliance (e.g., metal-to-metal contact). They require minimal angular movement and reach torque quickly.

- Soft Joints: Assemblies that compress soft materials like gaskets. They exhibit longer angular travel before reaching torque.

Tool calibration and strategy must be adjusted to the joint type. A one-size-fits-all approach can result in inconsistent torque application, missed quality targets, or over-stressing of components.

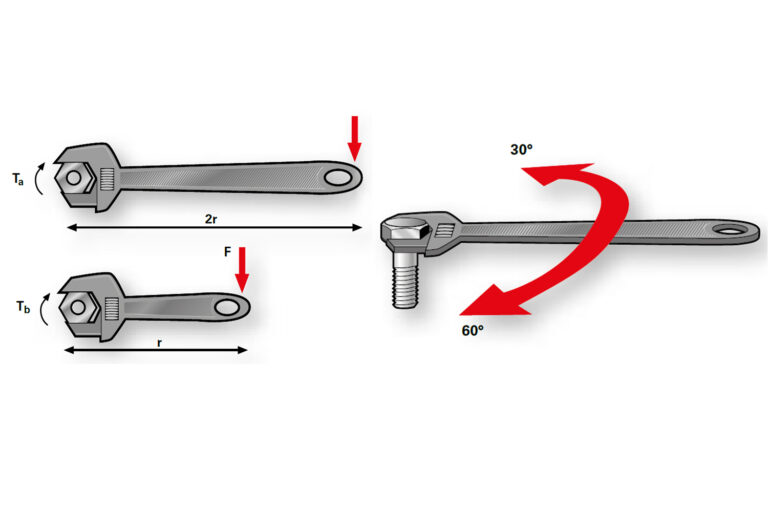

VII. Torque and Angle: Dual Variables for Process Control

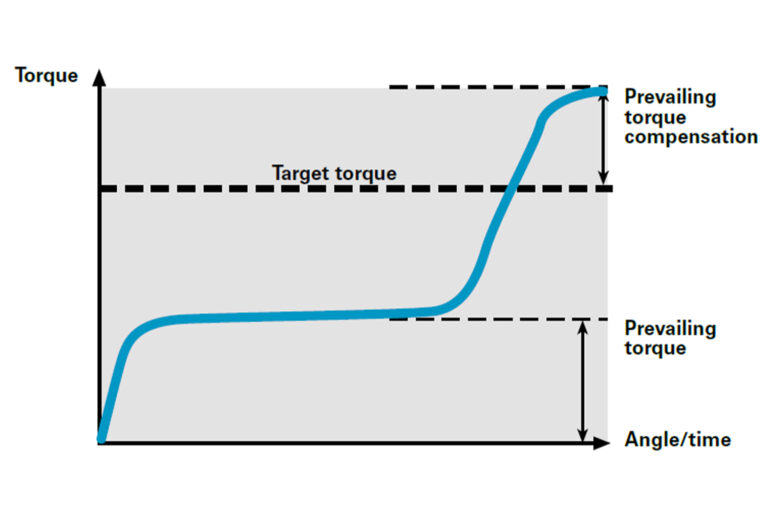

Torque alone is not enough to guarantee quality, especially when missing components (like washers) or damaged threads alter joint behavior. Combining torque control with angle measurement creates a more robust process.

This dual-variable method enables:

- Verification of joint component presence (by comparing angle-to-torque ratios)

- Identification of yield points (for tightening into plastic deformation regions)

- Improved repeatability in automated assembly

Advanced tightening strategies often use torque-angle signature profiles to detect anomalies in real-time.

VIII. Measurement Methods: Static vs. Dynamic

There are two primary methods for measuring torque:

- Static Measurement: Taken post-tightening using torque wrenches. It is simple and common but vulnerable to relaxation effects and user variability.

- Dynamic Measurement: Taken during the tightening cycle using transducers or integrated sensors. This method offers superior accuracy and real-time feedback but requires more complex tooling.

For critical joints, dynamic measurement is indispensable—especially when full traceability or certification is required.

IX. The Tightening Process: Where Technique Meets Tool

In any fastening application, how a tool applies torque is just as important as the torque value itself. Section 9 of the Atlas Copco Pocket Guide emphasizes this principle, underscoring that tightening technique significantly influences joint quality—and that power tools, when chosen correctly, enhance both speed and consistency.

Direct-driven tools like screwdrivers and nutrunners operate by applying a continuous torque until a predetermined value or stall point is reached. Their design ensures that torque application is controlled and efficient. Meanwhile, tools like impact wrenches and pulse nutrunners use intermittent bursts of energy, offering lightweight, powerful solutions with minimal reaction force. While ideal for certain industrial settings, these tools are less suitable for applications requiring precise torque monitoring.

X. Understanding Mean Shift: Torque Variance Across Joint Types

Different joint “hardness” levels can dramatically affect the final torque delivered. For example, hard joints absorb energy quickly, causing torque overshoot due to momentum, while soft joints compress slowly, resulting in lower dynamic torque transfer. This difference, called mean shift, creates inconsistencies if not managed carefully.

To counteract mean shift, engineers use shut-off tools with high-quality clutches, and sometimes adopt strategies like dual-stage tightening or angle-based control systems.

XI-XII. Tightening Standards and Certification Requirements

Mean Shift refers to the torque variation resulting from joint stiffness. On hard joints, torque builds rapidly, leading to overshoot as the tool’s internal momentum continues post shut-off. On soft joints, this overshoot is absorbed by the joint’s compliance.

Tool design must account for this dynamic discrepancy. High-speed tools must balance torque delivery with response time. Shut-off clutch quality, angular velocity, and gear ratios are all factors influencing mean shift. Engineers must validate tool performance across joint types to ensure consistency.

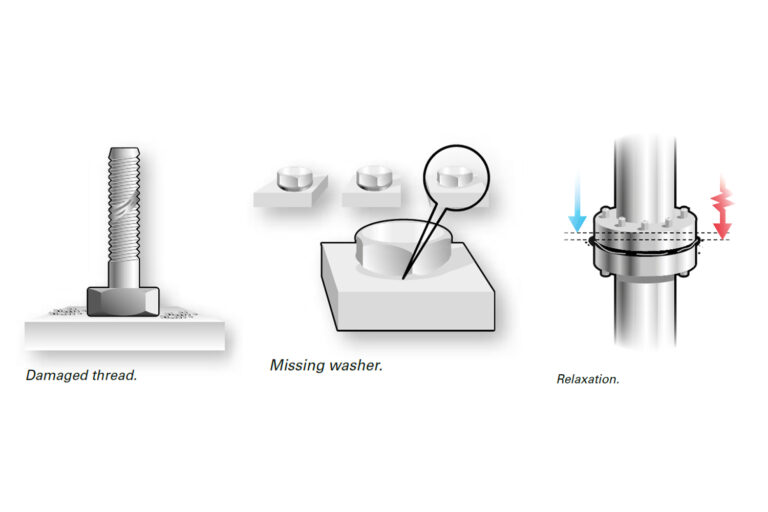

XIII-XVII. Common Tightening Errors & How to Avoid Them

Even the most advanced tool will underperform if fundamental issues are overlooked. These include:

- Damaged or dirty threads, which cause premature torque buildup without achieving adequate preload.

- Missing or incorrect washers, which change the torque-tension relationship.

- Material relaxation, where compressed gaskets or soft components reduce clamping force post-assembly.

- Prevailing torque elements, like nylon locknuts, which can be mistaken for resistance by torque-controlled tools.

These issues can result in under-torqued or over-torqued joints unless accounted for during setup and tool selection.

XVIII. Matching Tools to Application Demands

Selecting the right torque tool starts with understanding the production environment, fastener type, and required documentation level. Here’s a breakdown of common tool types and their best-use scenarios:

Lightweight and fast, pneumatic tools are commonly used in high-volume assembly operations. Options include stall tools, slip-clutch tools for general use, and shut-off clutch versions that offer better accuracy.

Electric tools offer digital control and are ideal for facilities requiring precision torque, angle monitoring, and traceable outputs. They also reduce dependency on air supply systems.

Modern battery tools combine the freedom of cordless operation with sophisticated torque control and feedback systems. These are suitable for flexible manufacturing setups, rework stations, and mobile assembly environments.

Tool Selection Overview

Here’s a quick reference to help align tool choice with application demands:

| Tool Type | Best Suited For |

|---|---|

| Impact Wrenches | Heavy maintenance, high-torque fasteners, low-precision environments |

| Pulse Tools | Medium-precision production lines, where low reaction force is a priority |

| Pneumatic Screwdrivers | High-speed, small-fastener tasks in assembly lines |

| Angle Nutrunners | Compact assemblies with tight access and high torque accuracy |

| Transducerized Tools | Critical fastenings with traceability and programmable tightening strategies |

| Reporting Pneumatic Tools | Error-proofing fastener applications in automotive and electronics |

| Electric Nutrunners | Assembly with traceable torque/angle control in lean production environments |

| Fixtured Spindles | Automated or multi-spindle applications where speed and repeatability are key |

| Battery Tools | Portable or mixed-model assembly lines needing flexibility and precision |

Building Tightening Strategies That Scale

When paired with sound fastening technique and a strong understanding of joint behavior, the right tightening tools elevate your quality standards and reduce risk throughout the product lifecycle.

By applying best practices and the right technologies, manufacturers can avoid the most common torque pitfalls and deliver reliable, compliant, and safe products at scale.