Home > Torque Trouble > Cleco Tools

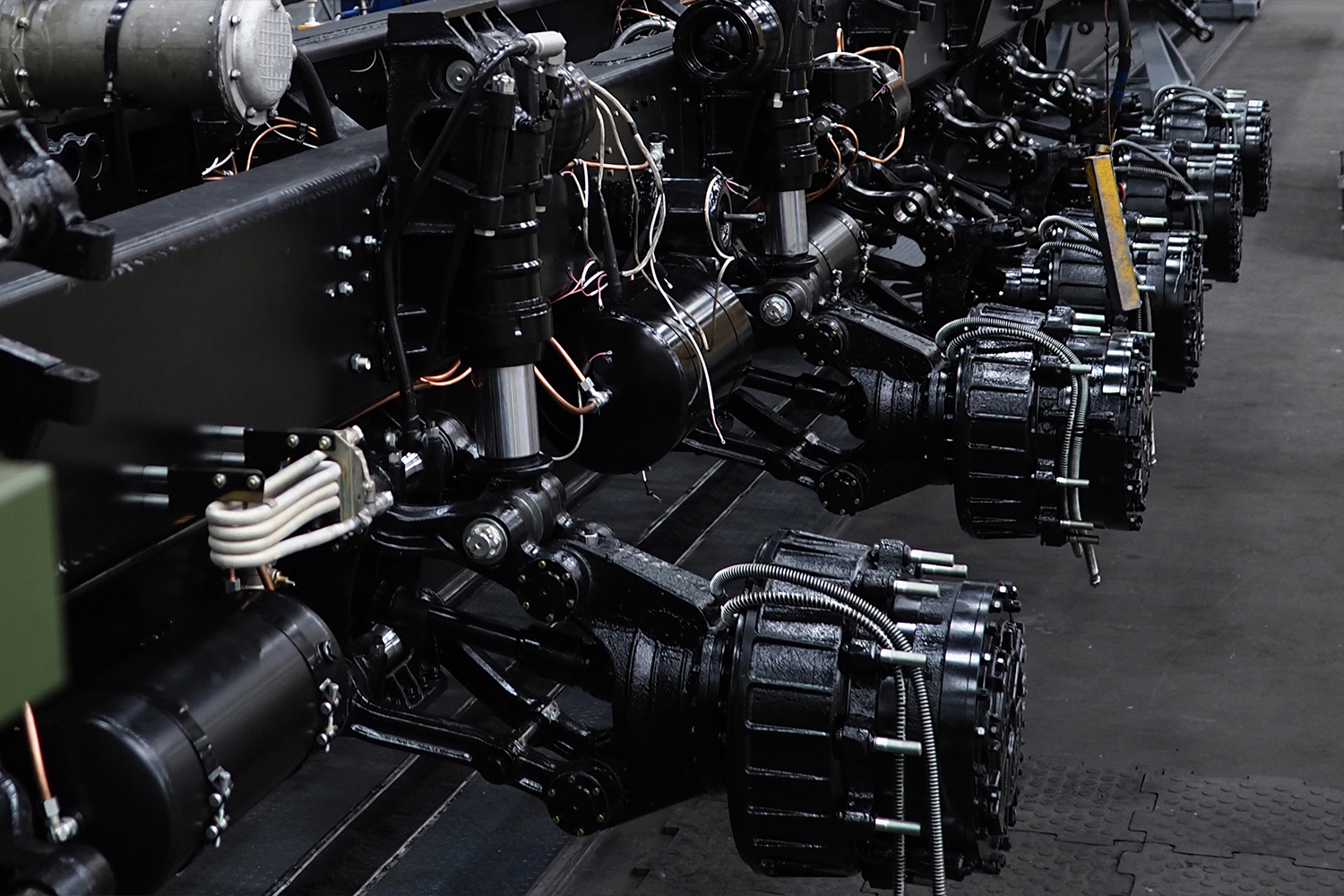

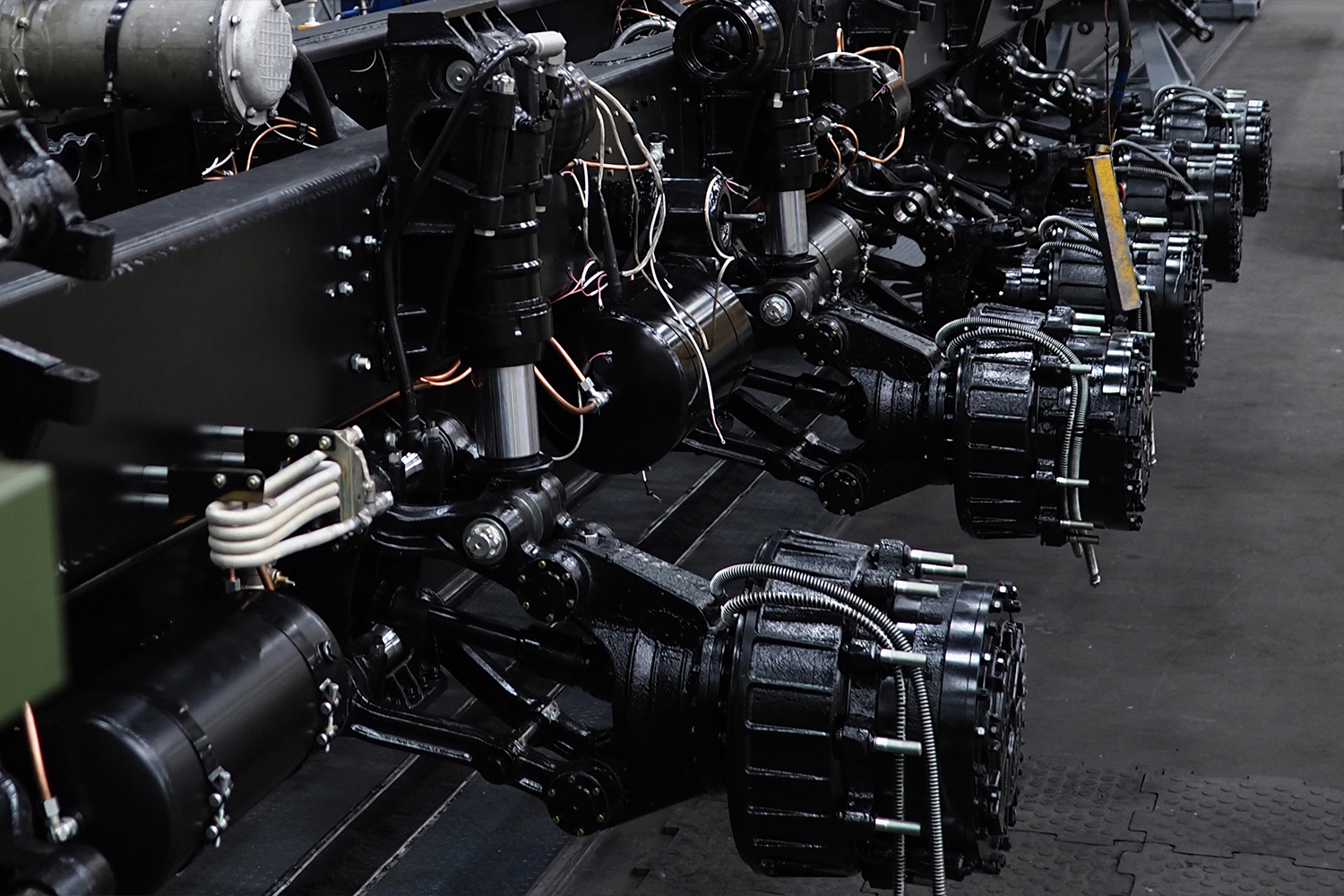

When it comes to building heavy-duty vehicles — whether it’s an 18-wheeler barreling down the interstate, a trailer hauling tons of freight, or a combine harvester working a 16-hour day in the field — there is no room for error.

Originally engineered for high-volume production environments, the CellClutch platform has become an essential tool in engineering, prototyping, and R&D labs – places where the future of manufacturing is born.

With features like programmable torque settings, multi-stage rundowns, batch counting, and wireless data connectivity, CellClutch Tools deliver the flexibility, accuracy, and traceability required to thrive in high-mix, high-complexity production environments.

Whether in a cleanroom assembling diagnostic equipment, on a circuit board line building IoT sensors, or fitting medical enclosures on a final assembly line, CellClutch tools deliver the control and intelligence modern precision manufacturing demands.

Built for rugged environments, Cleco CellClutch tools deliver reliable torque control and durability for energy, mining, and construction applications—where power, safety, and precision matter most.

Cleco CellClutch tools ensure consistent, programmable torque for industrial machinery and robotics assembly, ideal for complex builds, precision fastening, and high-reliability automation systems.

Cleco CellClutch tools improve quality and reduce rework in large appliance and consumer electronics assembly, offering precise torque shut-off and user-friendly control.

From structural airframe assembly to MRO torque tasks, Cleco CellClutch tools deliver precision, repeatability, and ergonomic control in demanding aerospace environments.

Cleco CellClutch tools enhance torque precision and reduce operator fatigue in automotive and heavy vehicle assembly: ideal for frames, suspensions, and drivetrain installs.

Discover how Cleco CellClutch cordless tools improve torque control, safety, and productivity across industries like automotive, aerospace, and electronics.

Not all torque wrenches are created equal. This guide compares micrometer, dial, electronic, and preset Cleco torque wrenches—highlighting the strengths, ideal use cases, and key differences between each to help you choose the right tool for your application.

When it comes to building heavy-duty vehicles — whether it’s an 18-wheeler barreling down the interstate, a trailer hauling tons of freight, or a combine harvester working a 16-hour day in the field — there is no room for error.

Originally engineered for high-volume production environments, the CellClutch platform has become an essential tool in engineering, prototyping, and R&D labs – places where the future of manufacturing is born.

With features like programmable torque settings, multi-stage rundowns, batch counting, and wireless data connectivity, CellClutch Tools deliver the flexibility, accuracy, and traceability required to thrive in high-mix, high-complexity production environments.

Whether in a cleanroom assembling diagnostic equipment, on a circuit board line building IoT sensors, or fitting medical enclosures on a final assembly line, CellClutch tools deliver the control and intelligence modern precision manufacturing demands.

Built for rugged environments, Cleco CellClutch tools deliver reliable torque control and durability for energy, mining, and construction applications—where power, safety, and precision matter most.

Cleco CellClutch tools ensure consistent, programmable torque for industrial machinery and robotics assembly, ideal for complex builds, precision fastening, and high-reliability automation systems.

Cleco CellClutch tools improve quality and reduce rework in large appliance and consumer electronics assembly, offering precise torque shut-off and user-friendly control.

From structural airframe assembly to MRO torque tasks, Cleco CellClutch tools deliver precision, repeatability, and ergonomic control in demanding aerospace environments.

Cleco CellClutch tools enhance torque precision and reduce operator fatigue in automotive and heavy vehicle assembly: ideal for frames, suspensions, and drivetrain installs.

Discover how Cleco CellClutch cordless tools improve torque control, safety, and productivity across industries like automotive, aerospace, and electronics.

Not all torque wrenches are created equal. This guide compares micrometer, dial, electronic, and preset Cleco torque wrenches—highlighting the strengths, ideal use cases, and key differences between each to help you choose the right tool for your application.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |