The Cleco CellClutch cordless tool series brings unmatched versatility, precision, and intelligence to the automotive and heavy vehicle manufacturing world. From powertrain assembly and EV battery integration to suspension systems and truck chassis builds, these tools provide the accuracy needed to meet today’s strict quality standards while delivering the ergonomic and digital advantages required for tomorrow’s smart factories.

By reducing rework, improving safety, and enabling seamless data integration, Cleco CellClutch tools help manufacturers increase productivity, lower total cost of ownership, and stay competitive in a rapidly evolving global market.

Precision and Performance: The Role of Cleco CellClutch Tools in Automotive & Heavy Vehicle Assembly

In the high-stakes world of automotive and heavy vehicle manufacturing, where safety, speed, and consistency are non-negotiable, the Cleco CellClutch series of cordless electric nutrunners offers a compelling solution. Designed for torque-critical operations across a range of fastening tasks, these tools blend the power and flexibility of cordless design with intelligent, programmable torque control—creating a platform ideally suited for modern assembly environments.

Industry Demands: Tight Tolerances, High Throughput

In automotive and heavy vehicle assembly, every fastener counts. Whether securing a seat frame to the chassis, bolting a bracket to an engine block, or assembling a truck’s suspension system, there are strict requirements for torque, angle, and repeatability. With growing pressures for higher throughput, leaner production lines, and tighter quality control, manufacturers require tools that not only meet mechanical performance demands but also integrate with data-driven manufacturing environments.

The Cleco CellClutch tool series—especially the CellClutch Cordless Electric Right Angle Nutrunners and CellClutch Cordless Electric Pistol Nutrunners—directly address these demands with a range of torque values (from under 2 ft-lb to over 60 ft-lb), real-time operator feedback, batch traceability, and optional wireless data communication. These features enable manufacturers to move faster without sacrificing safety or compliance.

Applications Across the Automotive Line

1. Powertrain Assembly

In powertrain assembly—particularly on engine and transmission lines—torque precision is paramount. Over-tightening a valve cover or leaving a critical bolt under-torqued can lead to catastrophic failure, costly recalls, or warranty claims. The CellClutch’s mechanical clutch and electronic shut-off offer CMK values greater than 1.67 at ±10% torque accuracy, meeting international quality standards such as ISO 5393.

Common applications include:

- Valve cover bolts

- Oil pan fasteners

- Timing cover installation

- Transmission case assembly

The multi-stage rundown function is especially useful in powertrain builds, allowing controlled torque stages with precise hold times to accommodate gasketing materials or thermal expansion tolerances.

2. Chassis Assembly

The chassis serves as the structural core of any vehicle, requiring robust fastening of load-bearing components such as:

- Suspension brackets

- Crossmembers

- Engine and transmission mounts

- Subframes and skid plates

These assemblies demand higher torque values—often exceeding 30 ft-lb—making Cleco’s higher-end CellClutch models (e.g., CLBA403 and CLBA653) ideal. The right-angle configuration allows access in tight vertical clearances, such as underbody stations or between frame rails, while the pistol grip versions offer ergonomic support for overhead or horizontal joints.

With no cords or air hoses, these tools offer improved operator mobility and reduce clutter on chassis lines—improving both safety and cycle time.

3. Interior & Trim Assembly

Unlike structural components, interior installations demand delicacy, ergonomics, and often work in confined environments. CellClutch tools provide low-torque options (1.6 ft-lb and up), allowing precise tightening of fasteners in:

- Seat frames and sliders

- Console brackets

- Dashboard components

- Door assemblies

The LED pass/fail indicators give operators immediate visual feedback for torque verification. This reduces rework and helps unskilled labor perform torque-critical operations with minimal training.

4. Battery Electric Vehicle (BEV) Modules

As automotive manufacturers rapidly adopt electric vehicles, battery integration has introduced new challenges. Battery packs must be sealed and bolted with tight tolerances, often using aluminum or composite enclosures. CellClutch tools shine here due to their:

- Programmable torque stages (helpful for layered sealing)

- Data logging (useful for warranty tracking)

- Compact, right-angle profile (access tight battery compartments)

Common applications in BEV production:

- Fastening battery enclosures to vehicle frame

- Installing thermal management modules

- Securing electric drive components

The tools’ integration into smart factory systems also supports traceability and predictive maintenance for EV production lines.

Applications in Heavy Vehicle Manufacturing

Heavy trucks, trailers, and agricultural equipment demand rugged tools that deliver high torque, survive tough environments, and allow for operator mobility across large-scale assemblies.

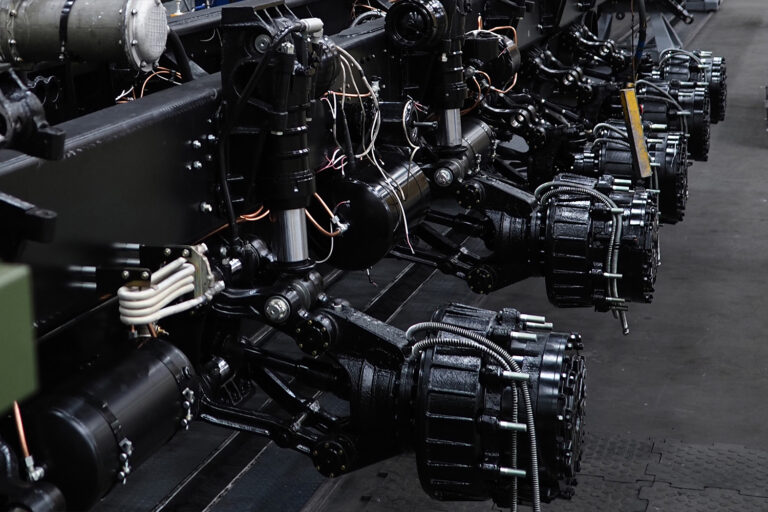

1. Driveline and Suspension Modules

Heavy vehicles utilize large, high-torque fasteners that secure:

- Axles and differentials

- Suspension arms and brackets

- Fifth-wheel couplers

- Drive shaft supports

Cleco CellClutch heavy-duty models provide up to 65 ft-lb of torque—eliminating the need for impact tools in medium torque ranges. With accurate torque control, they reduce over-torqueing risks that can damage components or compromise safety.

Cordless operation is especially valuable in trailer and truck factories, where workstations can span large footprints and fixed tool stations can slow production.

2. Cab and Frame Assembly

For Class 8 trucks and other heavy-duty vehicles, the cab is assembled in modules—interiors, control panels, external panels—all of which require consistent torque values. The CellClutch pistol model is ideal for:

- Instrument panel installation

- HVAC bracket mounting

- Seat rail and restraint system installation

Right-angle models are used in securing fuel tanks, battery boxes, and undercab accessories, offering ergonomic access where standard pistol tools fail.

Ergonomics and Safety for Assembly Workers

Right-angle models are used in securing fuel tanks, battery boxes, and undercab accessories, offering ergonomic access where standard pistol tools fail.

- Low reaction forces due to mechanical clutch shut-off

- Balanced center of gravity for pistol and right-angle configurations

- Battery platform compatibility with Milwaukee M18, reducing total battery management load

Cleco also emphasizes drop protection, with rugged construction that supports frequent handling in high-volume production settings.

Quality Assurance and Traceability

The CellClutch Connect line brings real-time data capabilities to the factory floor. With Wi-Fi and BLE 4.2, these tools communicate with Cleco’s mPro controllers or customer MES systems, transmitting:

- Torque results

- Batch counts

- Operator ID

- Workstation or model numbers

This is crucial in automotive, where traceability is a compliance requirement for OEMs and suppliers alike.

Pass/fail feedback, batch counters, and torque history logs support lean production practices and rapid root-cause analysis for defect reduction.

The CellClutch cordless system is part of a broader trend away from pneumatic tooling. Pneumatic systems require compressors, hoses, maintenance, and energy costs that scale poorly. Cordless electric tools reduce energy usage, eliminate tripping hazards, and allow production lines to be reconfigured rapidly.

For Tier 1 and Tier 2 automotive suppliers, the move to cordless represents both a cost-saving opportunity and a way to align with OEM sustainability goals. Cleco’s battery platform compatibility further simplifies adoption, and modular programmability allows a single tool to support multiple fastener types across different stations.