When it comes to building heavy-duty vehicles — whether it’s an 18-wheeler barreling down the interstate, a trailer hauling tons of freight, or a combine harvester working a 16-hour day in the field — there is no room for error. In these industries, durability, reliability, and efficiency are paramount. And that’s not just true for the vehicles themselves — it’s equally true for the tools used to assemble them.

Cleco’s CellClutch cordless tools are purpose-built to meet the intense requirements of truck, trailer, and agricultural equipment manufacturing. These are not light-duty tools for clean-room environments. They are engineered to thrive in sprawling factories, busy yards, and rugged industrial zones where high torque, repeatable results, and mobility matter most.

Industry Overview: Demanding Applications, Diverse Assemblies

The heavy vehicle and equipment sectors present a unique blend of challenges:

- Large, heavy fasteners that require consistent torque

- Massive component footprints that limit the reach of corded tools

- Highly repetitive processes that increase operator fatigue

- Vibration, shock, and environmental extremes that demand tool resilience

- Lean production goals that prioritize speed, accuracy, and data integration

From truck chassis and fifth-wheel couplings to tractor axles and hydraulic systems, the Cleco CellClutch lineup — particularly its right-angle cordless nutrunners — provides the torque, configurability, and rugged build required to assemble machines that work as hard as the people who operate them.

Key Applications in Heavy Truck Assembly

1. Diesel Engine Component Fastening

Diesel engines used in heavy-duty trucks are not only powerful—they’re massive. They house high-compression combustion chambers, large displacements, and multi-layered subassemblies. This means the bolts and fasteners required to keep everything secure are subject to intense vibration, heat cycling, and mechanical load. As a result, every bolt matters. Fastening engine components correctly is critical to performance, fuel efficiency, emissions compliance, and long-term reliability.

Torque Consistency Is Non-Negotiable

Engine fasteners must be torqued to precise values. Under-tightening leads to oil leaks, misalignment, or outright failure under pressure. Over-tightening can crush gaskets, crack aluminum castings, or deform mating surfaces—leading to premature engine wear or even catastrophic damage. Common components that demand strict torque adherence include:

- Valve covers and rocker arms

- Cylinder head caps and bolts

- Oil pans and timing chain covers

- Exhaust manifolds and turbocharger brackets

- Fuel system mounts and injection pump brackets

In many of these applications, it’s not just the final torque value that matters—it’s also how the torque is applied. Multi-stage torque strategies (snug > torque > angle hold) are often required to properly seat gaskets and distribute load across the surface without warping. Cleco CellClutch tools, especially the CLBA403 and CLBA653 models, are designed to manage exactly these kinds of jobs.

CellClutch Performance & Precision

Delivering torque up to 48 ft-lb, the CLBA403 and CLBA653 provide the necessary muscle for engine subassemblies while ensuring repeatability. Equipped with a mechanical clutch and electronic shutoff, these tools offer controlled disengagement at pre-set torque values—eliminating the risk of overtightening and drastically reducing operator-induced variation.

This precise shutoff mechanism helps protect:

- Thread integrity, especially in softer aluminum components

- Gasket compression limits, reducing rework caused by leaks or warping

- Joint alignment, essential in assemblies like intake runners and front-end accessory drives (FEADs)

Torque repeatability is especially critical in warranty-sensitive areas such as emissions systems, cylinder heads, and fuel injection components. The ability to document and verify proper torque during assembly plays a direct role in reducing warranty claims and improving long-term engine performance in the field.

Designed for Tight Spaces

Large diesel engines are densely packed, and fasteners are often located in tight recesses or behind components that haven’t been installed yet. The right-angle configuration of the CLBA series makes it possible to access mounting points that would be unreachable with traditional pistol-grip or inline tools. This is especially helpful when:

- Working between cylinder heads and exhaust components

- Installing oil pans with clearance restrictions around the crossmember

- Torquing fasteners in the engine bay where space is limited by frame rails, wiring harnesses, or cooling systems

The compact design and torque output make the right-angle version of CellClutch tools especially valuable on vertical engine stands, test cells, and in-chassis assembly lines.

Cordless Format = Ergonomic Advantage

Unlike pneumatic or corded electric tools, Cleco CellClutch tools are completely cordless—powered by widely adopted Milwaukee M18 batteries. For diesel engine assembly, this offers several significant benefits:

- No hoses or cables, which eliminates trip hazards and frees workers to move around the engine with fewer restrictions

- Faster cycle times, especially in workstations where the assembler must reposition frequently

- Lower operator fatigue, thanks to a lightweight magnesium body, well-balanced handle design, and reduced reaction force during clutch disengagement

- Improved tool control, especially in awkward angles or underbody work where tethered tools become cumbersome

This mobility is especially valuable in mixed-model production lines, where technicians must adapt quickly between engine sizes or configurations without moving their workstation or reconfiguring their tooling.

Productivity & Quality at Scale

Heavy truck manufacturers must build engines quickly—without sacrificing quality or compliance. Cleco’s torque programming features, including multi-stage rundown, torque hold-off, and batch counting, allow operators to:

- Apply torque in programmable stages to ensure gasket seating

- Prevent under/over-torque across multi-bolt patterns

- Confirm complete fastening cycles before moving to the next assembly

- Receive immediate pass/fail feedback via LED indicators

For manufacturers producing engines with emissions-critical systems like EGR valves, turbochargers, and high-pressure fuel pumps, this level of control reduces assembly error, minimizes scrap, and supports audit compliance (e.g., ISO/TS 16949).

Summary: Why It Matters

Assembling diesel engines is one of the most torque-sensitive applications in truck production. Mistakes made at this stage can cost thousands in rework, result in costly warranty claims, or lead to engine failure in the field. With the CellClutch CLBA403 and CLBA653, manufacturers and Tier 1 suppliers can:

- Deliver high torque with low variability

- Reach fasteners in confined engine compartments

- Reduce operator fatigue and improve line efficiency

- Integrate torque data into quality management systems (with Connect models)

In a production environment where uptime, throughput, and repeatability are critical, the Cleco CellClutch is not just a tool—it’s an essential part of a smarter, safer, and more scalable engine assembly strategy.

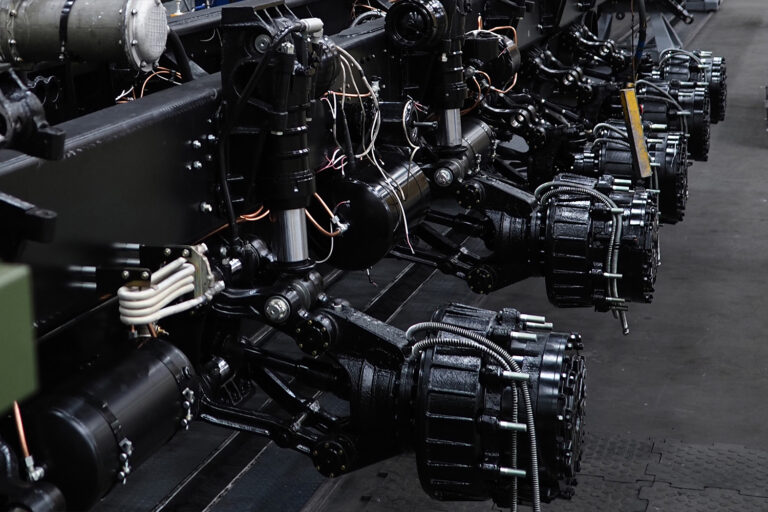

2. Driveline and Axle Assembly

The driveline is the backbone of a heavy-duty truck’s propulsion system. It transfers torque from the engine and transmission to the wheels, ensuring reliable power delivery and traction under varied operating conditions—from steep mountain grades to stop-and-go city hauling. That system includes several major components—driveshafts, axles, differentials, crossmembers, torque arms, and yokes—all of which must be precisely assembled and securely fastened to withstand long-term stress and prevent catastrophic failure.

The Cost of Inconsistent Torque

In driveline assembly, every bolt is load-bearing. A loose or improperly torqued fastener can result in:

- Driveshaft misalignment, leading to vibration, noise, or u-joint failure

- Cracked or warped differential housings, compromising oil seals and gear mesh

- Crossmember fatigue, resulting in frame stress or axle instability

- Complete detachment of critical components like yokes or hanger brackets during operation

These aren’t just quality issues—they are safety concerns. A failed driveline component on the highway can result in vehicle disablement, property damage, or serious injury.

That’s why torque precision is non-negotiable during the driveline and axle assembly process. Whether on a main production line or a Tier 1 axle supplier facility, assemblers need tools that are not only powerful and accurate, but also intelligent, configurable, and adaptable to each step of the build.

How Cleco CellClutch Tools Solve It

Programmable Torque and Speed for Versatility

Driveline fasteners vary widely in size and torque requirement. For instance:

- Driveshaft flange bolts may require moderate torque (~30–45 ft-lb)

- Differential housing bolts can range higher (~50–70 ft-lb)

- Suspension torque arms and crossmembers demand precision preload sequences

Cleco CellClutch tools offer programmable speed and torque profiles that allow technicians to:

- Customize each rundown to match specific fastener materials, lubrication conditions, and joint geometry

- Slow tool speed near final torque, improving control and reducing over-travel

- Apply maximum RPM for snugging bolts, then reduce RPM for precision seating

With a mechanical clutch shutoff backed by electronic control, the CellClutch consistently disengages at the exact torque value—ensuring repeatability across hundreds of cycles.

Multi-Stage Rundown Capability

Many driveline assemblies require a multi-stage torque process, often to:

- Preload the bolt (e.g., to 50% torque)

- Allow for joint settling or elastic deformation

- Final-torque to full value, often with a hold-off or dwell period

- Optional: apply torque + angle for critical parts like u-joint flanges

Cleco’s multi-stage rundown programming supports these needs directly on the tool—no external controller needed (unless using Connect versions). This means technicians can preload and finish torque cycles in one motion, increasing speed and consistency.

For example:

- A tech can set a 35 ft-lb preload, pause for seating, and apply a 48 ft-lb final torque in one sequence.

- Tools can be programmed for torque-to-yield strategies common in axle center section caps.

This helps eliminate under-torqued or over-seated fasteners, especially when working with large-diameter bolts that compress gaskets or structural joints.

Real-Time Feedback and Quality Assurance

Fastener inspection in driveline assembly is difficult. Many bolts are recessed, shielded, or blocked by housings. Manual torque check after assembly can be time-consuming or unreliable.

Cleco CellClutch tools solve this by providing:

- Visual pass/fail indicators (LEDs) that confirm successful rundown

- Audible alerts for incomplete or failed torque events

- Batch counting to confirm all required bolts are completed before moving on

- Data logging and wireless traceability (in Connect versions) for QA documentation

This eliminates guesswork and reduces dependence on manual post-checks or spot auditing. If a rundown fails, the tool notifies the operator immediately—allowing correction on the spot.

For high-throughput driveline operations, this saves time, labor, and rework.

Configurations for Complex Assembly Layouts

Driveline systems are often pre-assembled in modules or built under the chassis, depending on production layout. Accessibility to torque points varies greatly:

- Axle fasteners may require vertical access through a pit or lift

- Driveshaft flanges are often mounted deep between frame rails

- Crossmember and bracket bolts may be positioned under the frame or within tight weldments

That’s why Cleco offers the CellClutch in both pistol-grip and right-angle configurations. Each offers unique ergonomic and reach advantages:

- Pistol-grip models are ideal for exposed assemblies or workstation builds with easy top-down access

- Right-angle models excel in low-clearance areas, such as undercarriage stations, where reaching around brackets or into subframes is necessary

This adaptability allows manufacturers to standardize on one tool family while customizing to each task’s geometry and ergonomics—reducing training time and tool inventory.

Ergonomics and Cordless Efficiency

In driveline assembly, technicians often work on parts mounted at awkward angles, overhead, or on mobile carts. Traditional pneumatic tools require tethering to air hoses, which:

- Add weight and resistance

- Cause hose drag and trip hazards

- Limit reach and flexibility

Cleco CellClutch tools operate cordlessly using Milwaukee M18 batteries, eliminating all of those limitations. This:

- Increases operator comfort and freedom of movement

- Reduces cycle time, especially for under-frame workstations

- Allows tools to be used anywhere on the line or in off-line subassembly areas

This level of mobility is especially important for multi-station axle module builds and when working inside jigged subframes.

Summary: Confidence in Every Rotation

Driveline and axle assembly is high-stakes work. A single improperly torqued bolt can take a truck off the road, damage expensive components, or compromise safety.

The Cleco CellClutch platform ensures every critical fastener receives the correct torque—regardless of where it’s located or how often it must be repeated. With programmable control, ergonomic adaptability, and real-time quality assurance, Cleco tools give manufacturers the confidence to build structurally sound, high-performance driveline systems, shift after shift.

In the world of heavy truck production, where uptime matters and every bolt is under load, precision isn’t optional—it’s a requirement. Cleco delivers.

3. Chassis and Suspension Modules

The chassis is the structural foundation of every heavy-duty truck—a rigid framework that supports everything from the cab to the drivetrain to the load-bearing suspension. Building it is a complex, physically demanding process involving hundreds of torque-critical fasteners that secure key components such as:

- Main frame rails and crossmembers

- Steering gear mounts and torque arms

- Leaf spring hangers and suspension brackets

- Cab and engine mounting points

- Fuel tank brackets and battery trays

These assemblies must withstand constant flex, vibration, braking forces, and road shock over millions of miles. Mistakes in this stage don’t just affect build quality—they can undermine the entire vehicle’s durability and safety.

The Demands of Chassis Assembly

Unlike confined engine compartments or modular subassemblies, chassis assembly is mobile and expansive. Workers often move along the length of a 20- to 30-foot frame, fastening critical components overhead, below waist level, and from multiple orientations. These jobs require tools that offer:

1. High Torque Output

Chassis fasteners are typically large bolts—grade 8 or higher—and often torqued between 35 ft-lb and 60 ft-lb or more. They must resist:

- Lateral twisting from torsion and turning

- Longitudinal strain from braking and acceleration

- Vertical compression from cargo and suspension loading

Torque errors at this level can lead to weldment cracks, misalignment of suspension geometry, and failure of bolted joints under load.

2. Full-Day Ergonomics

Assembly techs may install hundreds of bolts per truck, each requiring forceful, repetitive movements. Without ergonomic tools, the risk of fatigue, repetitive strain injuries (RSIs), and accuracy lapses increases significantly.

3. Freedom of Movement

Chassis production lines are long, often segmented, and require tools that move with the operator, not the other way around. Air hoses, power cords, and torque verification stations can cause:

- Tripping hazards

- Limited range and awkward positioning

- Delays during station transitions or tool reconfiguration

How Cleco CellClutch Tools Excel in Chassis Assembly

Cordless Mobility Across the Frame

Cleco CellClutch tools are 100% cordless, powered by Milwaukee M18 batteries. This untethers workers from the limitations of air lines and cords, allowing technicians to:

- Walk freely down the length of the chassis, fastening brackets, hangers, and crossmembers without repositioning or unplugging tools

- Reach under-frame components or overhead brackets without fighting hose drag

- Quickly reposition between left/right or front/rear stations for multi-user assembly zones

This mobility is particularly beneficial in takt-based production systems, where every second counts and delay at one station can ripple across the entire line.

High Torque Performance Without Overload

Cleco’s CLBA403 and CLBA653 models are ideal for chassis assembly, offering torque output up to 48 ft-lb—perfect for:

- Frame rail mounting points

- Leaf spring shackle bolts

- Fuel tank or DEF tank supports

- Cab and step brackets

Each CellClutch tool includes a mechanical clutch with electronic shutoff, ensuring that torque is consistently applied and disengaged at the precise spec—preventing overtightening, thread stripping, or bolt head deformation.

Precision and Repeatability on the Line

With built-in programmable torque profiles, CellClutch tools allow:

- Custom torque values for different chassis zones (e.g., suspension vs. cab mounts)

- Multi-stage rundown (e.g., snug torque + final torque + hold)

- Reduction of torque scatter, even with operator hand-position variance or fatigue

This level of programmability ensures that every bolt gets the correct torque, the first time, regardless of where it is on the frame or who is performing the operation.

Visual and Audible Operator Feedback

Visual and audible cues are critical when tools are used in fast-paced, high-noise environments like truck chassis lines. CellClutch tools are equipped with:

- LED pass/fail indicators on the tool body

- Audible buzzers for successful/failed torque applications

- Vibration signals (optional on Connect models) for haptic reinforcement in loud areas

This real-time guidance reduces:

- Dependency on manual verification or post-process checks

- Missed fasteners due to distractions or fatigue

- The need for costly rework stations downstream

By confirming proper torque application during the fastening process, CellClutch tools improve first-pass yield—ensuring that trucks continue down the line only when structurally sound.

Batch Counting for Verification and Process Control

Every chassis has a known fastener count and sequence. Missing a bolt in a crossmember or cab mount isn’t just a mistake—it’s a failure waiting to happen. CellClutch tools include:

- Batch counting modes that track fasteners per task or station

- Lockout options that prevent tool use until all bolts in the batch are completed

- Programmable rundown sequences, so operators follow standard tightening patterns (e.g., alternating crossmember bolts)

Supervisors and quality engineers can monitor completion status in real-time, ensuring that every bolt has been accounted for before the vehicle moves to the next station. This improves line accountability while reducing reliance on after-the-fact inspections.

Ergonomics Designed for Shift-Long Use

Tool ergonomics are crucial in full-shift chassis operations. Cleco CellClutch tools are engineered with:

- Lightweight magnesium housings

- Well-balanced grips, minimizing wrist strain

- Low reaction force due to the controlled clutch disengagement

- Tool-only programming, eliminating the need for awkward tablet setups or remote controls

These features help technicians stay comfortable and accurate through long production shifts—particularly important in high-turnover environments or where rotating teams must work at speed.

Connect Tools for Smart Factory Integration

For advanced manufacturing environments, CellClutch Connect models bring added digital traceability and process intelligence:

- Wi-Fi and Bluetooth connectivity allows torque data to be logged in real-time

- Integration with MES or QA systems, tying fastener results to VINs or work orders

- Remote reprogramming of torque profiles, reducing downtime and manual setup

- Operator ID tracking, ensuring accountability by shift, team, or individual

In chassis and suspension module assembly, where joint integrity and quality documentation are critical, this kind of digital oversight reduces defects, improves traceability, and supports ISO/TS compliance.

Summary: Building on a Solid Foundation

The chassis and suspension module is quite literally the foundation of the truck. Errors here echo through the entire vehicle—from how it handles to how long it lasts. With Cleco CellClutch cordless tools, manufacturers gain a powerful advantage:

- High torque precision for structural fasteners

- Mobility across long workstations

- Operator guidance and feedback that reduces mistakes

- Data traceability and batch control that support quality audits

- Ergonomic and modular tool formats that boost productivity without increasing strain

In the demanding world of heavy-duty truck production, where uptime, safety, and precision are paramount, Cleco ensures that every bolt is right—right from the start.

Applications in Trailer Manufacturing

Unlike automotive plants, trailer manufacturing facilities often lack conveyorized lines. Workstations are widely spaced, trailers may be positioned on stands or skids, and workers often climb, kneel, or crawl to reach fastening points.

CellClutch tools are perfectly adapted for this environment:

- No cords or hoses = total mobility

- Battery operation (using widely available Milwaukee M18 batteries) means charging logistics are simple and scalable

- Durable magnesium housing resists drops, dust, and daily abuse

Common uses include:

- Fastening floor frames and crossmembers

- Installing brake system brackets and air tank mounts

- Assembling roof bows and corner posts

Programmable rundown settings let the same tool perform different tasks along the trailer, improving efficiency and reducing the number of tools needed on hand.

Applications in Agricultural Equipment Assembly

Building tractors, combines, sprayers, and other agricultural machinery involves even more extreme considerations. These vehicles are made to operate in mud, heat, vibration, and constant abuse — and the tools that assemble them must match that level of resilience.

Key tasks include:

- Securing large hydraulic system brackets

- Installing paneling and guards

- Attaching suspension and lift systems

- Mounting engine and transmission subassemblies

Cleco CellClutch tools give ag equipment assemblers:

- High torque output (up to 60 ft-lb depending on model)

- Precision control to avoid damaging large threaded bores

- Data tracking to comply with manufacturer QA standards

Right-angle cordless tools are ideal for cramped assembly spaces within combines and tractors, especially where overhead work is required. Their ergonomic balance and lightweight body reduce worker strain in long assembly shifts.

Operator Benefits and Ergonomic Design

Across all three sectors — trucks, trailers, and agriculture — line workers benefit directly from features that reduce fatigue, improve safety, and increase confidence on the job:

- LED pass/fail lights and optional buzzer provide clear, instant feedback

- Mechanical clutch shutoff eliminates dangerous torque kickback

- Magnesium construction keeps weight low while maintaining strength

- Tool-only programming allows on-the-fly adjustments without tethering to a PC

- Multi-position handles improve ergonomics across various tasks and orientations

These design details may seem minor, but in large-scale production environments where a technician performs the same motion hundreds of times per shift, they add up to meaningful differences in comfort, safety, and productivity.

Connected Assembly: Data in Real Time

Modern truck and equipment OEMs increasingly rely on traceability and digital integration to ensure quality and accountability.

The CellClutch Connect line delivers:

- Wi-Fi & Bluetooth connectivity (2.4/5 GHz and BLE 4.2)

- Live torque reporting and rundown validation

- Integration with MES systems or Cleco’s mPro controllers

- Batch counting and operator tracking

In practice, this means:

- Supervisors can confirm every critical bolt on a truck frame was torqued to spec

- Engineers can diagnose torque problems or variances immediately

- Operators get instant error notification and feedback for correction

Whether for ISO 9001 compliance, customer warranties, or simply building better machines — this level of data control is becoming the norm, and CellClutch is ready.

Conclusion

Heavy truck, trailer, and agricultural equipment assembly demand tools that are not only powerful, but smart, resilient, and ergonomic. The Cleco CellClutch cordless series meets that demand head-on, delivering a mobile, programmable fastening solution designed for the toughest jobs in manufacturing.

With high torque options, configurable rundowns, integrated QA features, and unmatched cordless mobility, CellClutch tools empower technicians to build with speed, precision, and confidence — whether they’re bolting a transmission mount, outfitting a trailer frame, or assembling a combine destined for the harvest field.

In industries where strength meets precision and durability meets data, Cleco delivers.