From consumer electronics to aerospace and automotive labs, screwdriving demands precision, consistency, and repeatable results. Behind every high-quality joint lies the right combination of tightening method, clutch technology, and torque control strategy.

This guide combines industrial best practices with torque tool insights to help manufacturers improve quality, minimize rework, and empower operators with confidence and control.

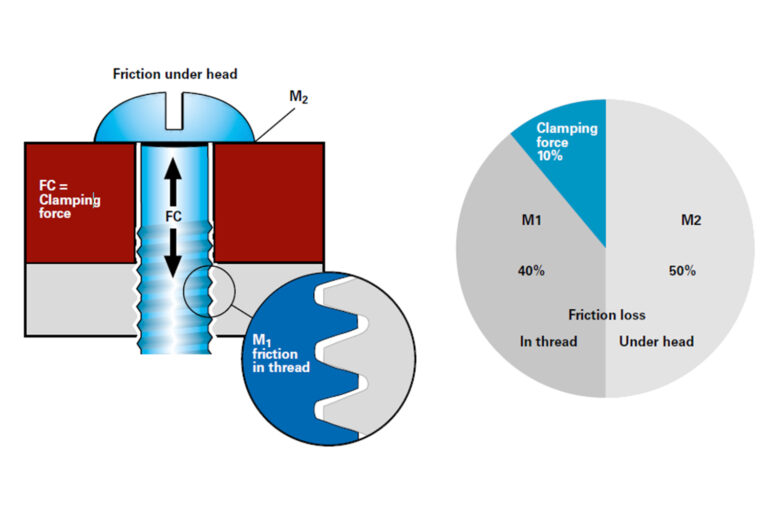

Torque vs Clamping Force: The Real Goal

The catch? As much as 90% of torque is lost to friction in the threads and under the head of the screw. That means even with torque-controlled tools, your final clamp load can vary significantly if materials, lubrication, or hardware tolerances shift.

That’s why it’s crucial to:

- Match the tool to the joint type

- Minimize friction variability

- Use torque/angle control or shut-off clutches in precision-critical environments

Tool Technology: What Sets Screwdrivers Apart?

Not all torque screwdrivers are created equal. Internally, tools vary widely based on their drive type, clutch mechanism, and power source—each of which impacts torque accuracy, user fatigue, and long-term reliability.

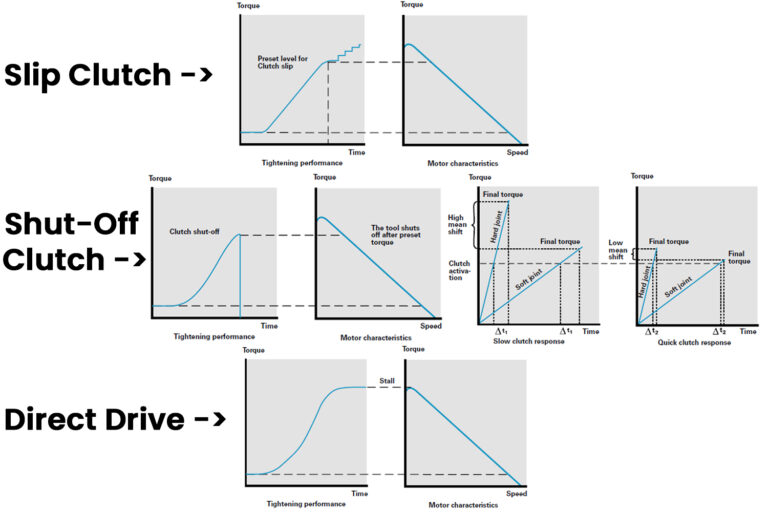

Clutch Mechanisms

| Clutch Type | Strengths | Tradeoffs |

|---|---|---|

| Slip Clutch | Simple, cost-effective, friction-sensitive | Low accuracy, prone to overrun |

| Shut-Off Clutch | Precise, consistent, clean disengagement | More complex, dependent on clutch reaction time; costlier |

| Direct Drive | Durable and compact | Depends on operator judgment; low accuracy |

When precision and repeatability matter—like in electronics or medical assembly—shut-off clutches are the superior choice.

For rugged or thread-forming applications like HVAC ducting or woodwork, slip clutches and direct-drive tools provide simplicity and speed.

Power Source Comparison

Selecting the right drive mechanism ensures consistent results and meets operational constraints (noise, mobility, maintenance).

- Match the tool to the joint type

- Minimize friction variability

- Use torque/angle control or shut-off clutches in precision-critical environments

| Power Source | Ideal Use | Benefits |

|---|---|---|

| Pneumatic | High-speed, high-volume assembly | Lightweight, durable, fast cycle times |

| Low-voltage DC | Electronics, ESD-safe production lines | Quiet, precise, easy integration |

| Battery Tools | Mixed-model assembly, mobile workstations | No hoses/cables, programmable shut-off |

| Current-Controlled | Aerospace, automotive, high-compliance lines | Torque/angle control, advanced diagnostics |

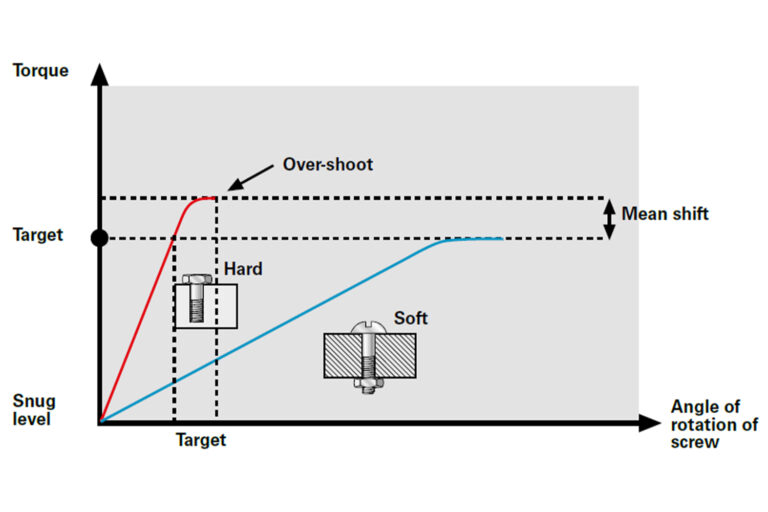

Understanding Joint Behavior

Torque control only works if the joint characteristics are accounted for. This includes:

- Hard joints: Fast torque rise, less rotation

- Soft joints: Slower torque rise, more rotation

- Prevailing torque joints: Friction present before seating (e.g., locknuts)

- Relaxing joints: Materials compress after torque, losing preload

Failure to consider these factors leads to mean shift, where tools apply different clamping forces to the same torque spec depending on joint stiffness.

This makes real-time verification and torque/angle monitoring critical in regulated industries—a concept explored further in our article on Torque Verification & Documentation.

Ergonomics: It’s Not Just About Comfort

In high-volume manufacturing, torque tool ergonomics are more than a luxury—they’re a necessity. Operators performing hundreds or even thousands of screwdriving cycles per shift are prone to:

- Wrist and shoulder strain

- Reduced consistency due to fatigue

- Long-term repetitive stress injuries

- Lower throughput from awkward hand positioning

One of the most powerful ways to combat ergonomic strain and operator fatigue and improve precision is choosing the right shape of tool for the task. Tool shape determines how naturally an operator can align their wrist, apply axial force, and maintain visual contact with the fastener.

Pistol Grip Screwdrivers

- Ideal for: Horizontal joints at or just below elbow height

- Why it works: Mimics the body’s natural push motion for forward-driving force

- Use cases: Automotive subassemblies, appliance housing, self-drilling screws

- Ergonomic benefit: Reduces wrist flexion and allows better control of medium-to-high torque tools

Straight (Inline) Screwdrivers

- Ideal for: Vertical joints (upward or downward) or when suspended from balancers

- Why it works: Keeps the wrist neutral and enables direct downward force

- Use cases: PCB assembly, small electronics, torque-controlled precision fastening

- Ergonomic benefit: Lightweight, easy to support with tool balancers for fatigue-free operation

Angle Head Screwdrivers

- Ideal for: Obstructed or recessed fasteners where front-facing access isn’t possible

- Why it works: 90-degree drive head provides lateral access to the fastener

- Use cases: Tight enclosures, aerospace compartments, HVAC panels

- Ergonomic benefit: Reduces awkward hand positions in limited-clearance work zones

Supporting Tools That Reduce Operator Strain

Even with the right tool shape, physical strain can accumulate. To optimize ergonomics further, manufacturers rely on:

- Tool Balancers to suspend straight screwdrivers

- Torque reaction arms (such as Mountz Torque Arms) to absorb kickback

- Push-to-start triggers reduce hand strain by requiring less finger pressure during repetitive fastening

Choosing the right tool shape for the job—and pairing it with ergonomic supports—is a proactive way to protect your workforce, improve consistency, and boost throughput.

Bit Selection and Tooling Accessories

Your driver bit is the only part of the tool touching the fastener—and yet it’s often overlooked. Key guidelines:

- Use hardened bits for metal or self-drilling screws

- Match bit profile precisely to the fastener head (not just Phillips vs Torx, but depth and fit)

- Replace worn bits regularly—worn tips reduce torque transfer and increase cam-out

Proper use of bit holders, quick-change adapters, and depth stops also improves accuracy and tool life.

Torque Testing and Process Control

To ensure tools continue performing correctly:

- Perform daily torque checks using a tool tester like the Sturtevant Richmont System 8 Digital Torque Tester

- Implement scheduled recalibration and certificate logging

- Use cycle counters on digital tools to plan preventative maintenance

This aligns with strategies discussed in Torque Problems: Slipping Torque Tools or Clutches That Don’t Engage.

Tool Selection Cheat Sheet

| Joint Type | Recommended Tool Style |

|---|---|

| Hard metal-to-metal | Shut-off clutch, moderate RPM |

| Gasketed soft joint | Slip or shut-off clutch, lower RPM |

| Thread-forming or self-drilling | High-RPM slip clutch or direct drive |

| Nylon insert locknuts | Shut-off clutch with torque+angle sensing |

| Wood or drywall screws | Direct-drive, pistol grip, high RPM |

Training & Standardization: The Human Factor

Even the best screwdriver is only as good as the person using it. Top-performing teams build:

- Standard operating procedures (SOPs) for torque tools

- Visual job aids to guide tool orientation and fastener specs

- Hands-on training for proper tool handling, bit selection, and troubleshooting

Investing in your team’s understanding of the tightening process ensures tools are used to their full potential, and that quality doesn’t depend on memory or guesswork.

Final Thoughts: Screwdriving Is a Precision Process

When assembly quality matters, screwdriving is never “just a task.” It’s a core element of product integrity. By aligning torque tools with joint behavior, operator needs, and verification strategies, manufacturers gain measurable improvements in:

- First-pass yield

- Fastener retention

- Operator satisfaction

- Audit readiness

- Long-term durability

Explore our full library of torque-related solutions to optimize your fastening process from every angle.